Description

HYGP-A100 Automatic Desktop Gear Pump Dosing Filling Machine

The automatic gear pump bottle filling machine has advantage of high accuracy when filling liquid and pure viscous liquid, cream, sauce, paste like peanut buffer, honey, noodle pulp, tomato paste etc. It is matched with servo motor and PLC to control filling. It is widely used in food, cosmetics, daily chemical industries.

Product Application

Food: Honey, jelly, jam, yogurt, cream, ice cream, eight treasure porridge, tomato paste, sesame paste, flour paste, maltose, mustard paste, mashed potatoes, bean paste, salad dressing, chocolate, yeast, butter, animal fat, cheese, cooking oil, juice, water, wine, liquor, etc.

Daily chemical products: Shampoo, shower gel, bath milk, soap, hand cream, hand washing liquid, perfume, sunscreen, water, nail polish, emulsion, moisturizing water, essence oil, toothpaste, cleansing cream, facial cream, essence oil, silica gel, rubbing treasure, detergent, laundry detergent, bleach and so on.

Other categories: Grease, lubricant oil, pet ration, Vaseline, cough syrup, industrial glue, white latex, glucose, gelatin, daphnetin, normal saline, paint, waterproof glue, etc.

Filling range

5ml-30000ml (customized)

Filling nozzle outer diameter

Customized according to bottle mouth

Filling accuracy

Filling speed

Control method

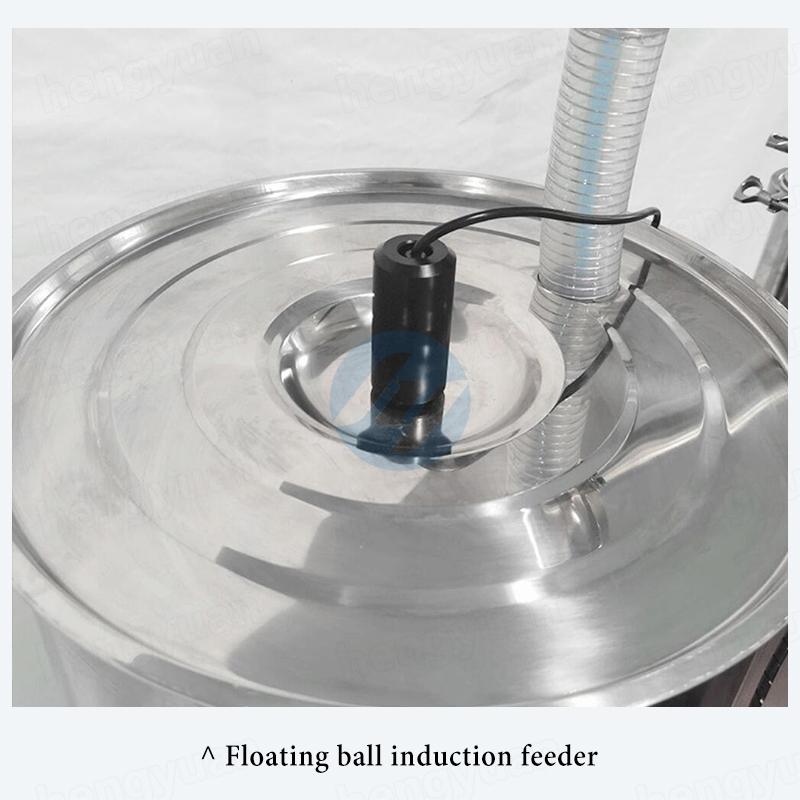

Hopper Optional Function

Volume of Hopper

Working air pressure

Operation voltage

1Electricity consumption

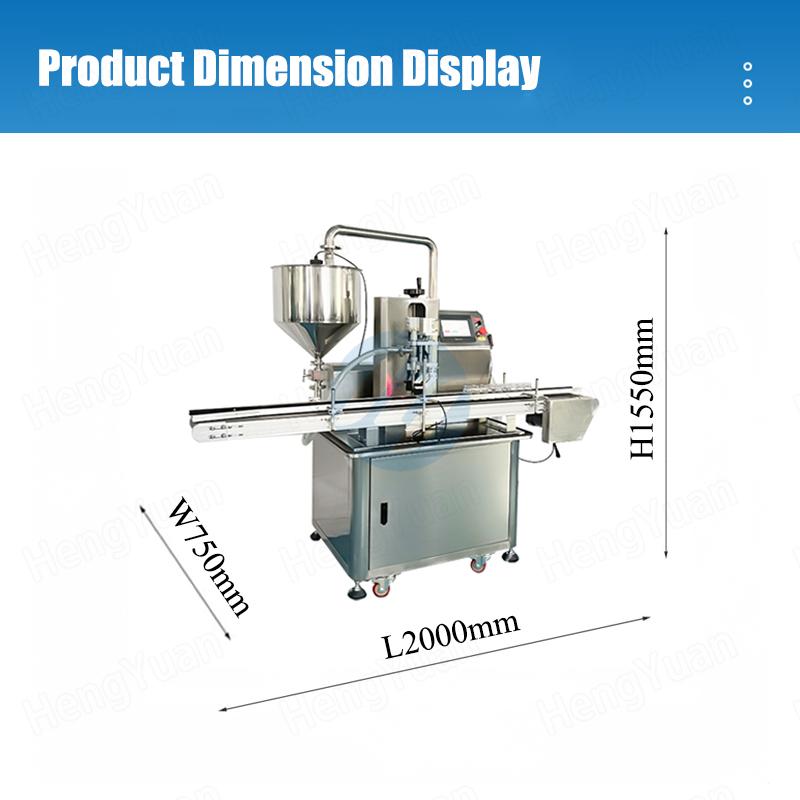

Machine size

Weight

Technical Parameters

≤±0.5%

60L/Minute ( Others can be customized)

Pedal or automatic intermittent

Stirring, insulation, pressurization

30L Vertial Hopper or 80L U Hopper

0.4-0.8Mpa

220V or 110V, Single phase.

1Kw

200*75*155cm

180Kg

Main Features

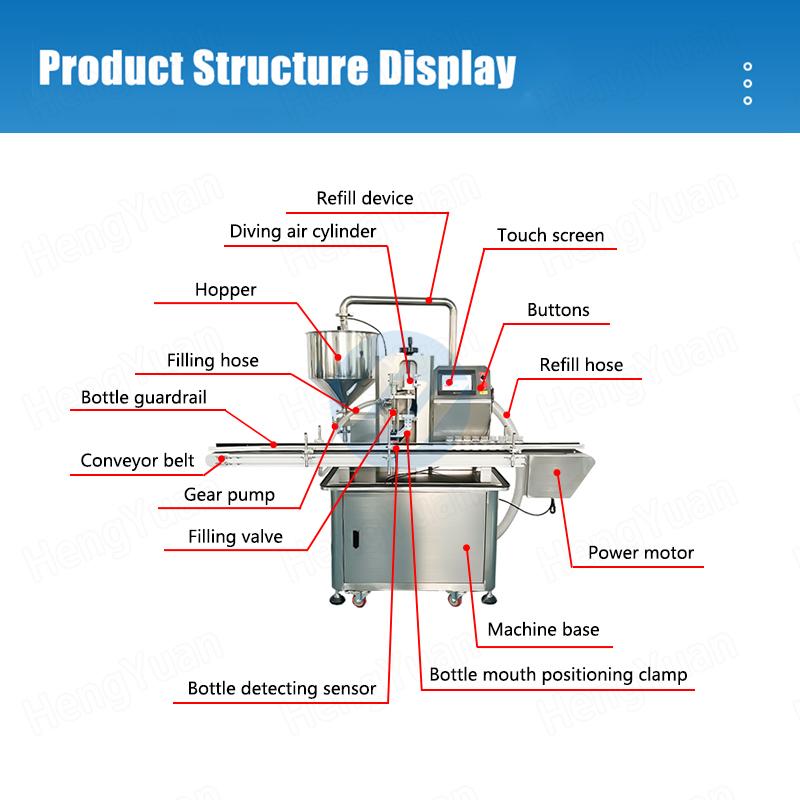

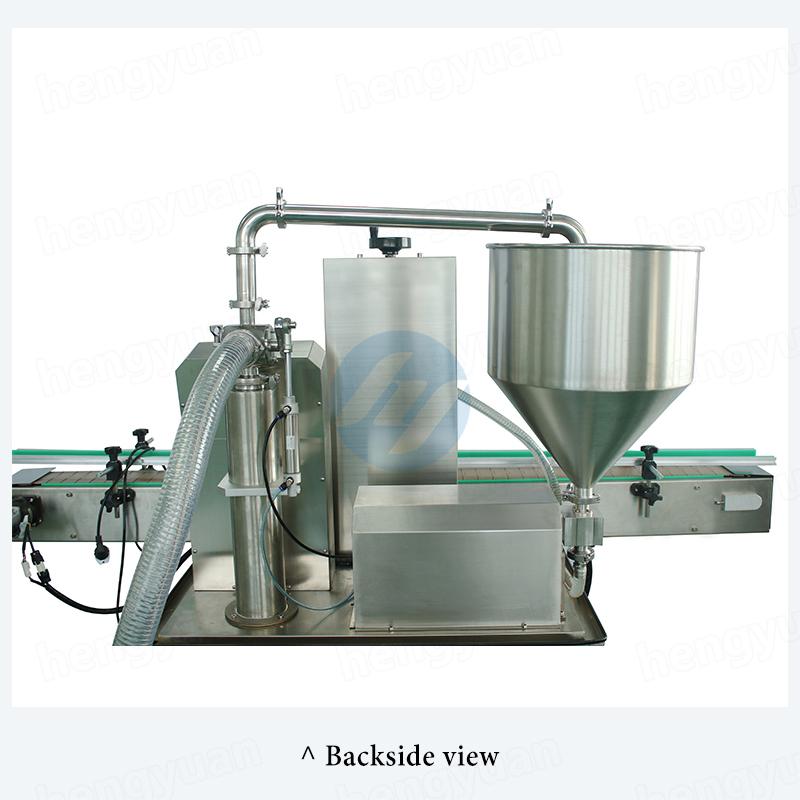

1) Simple structure in linear type, easy in installation and maintenance.

2) Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

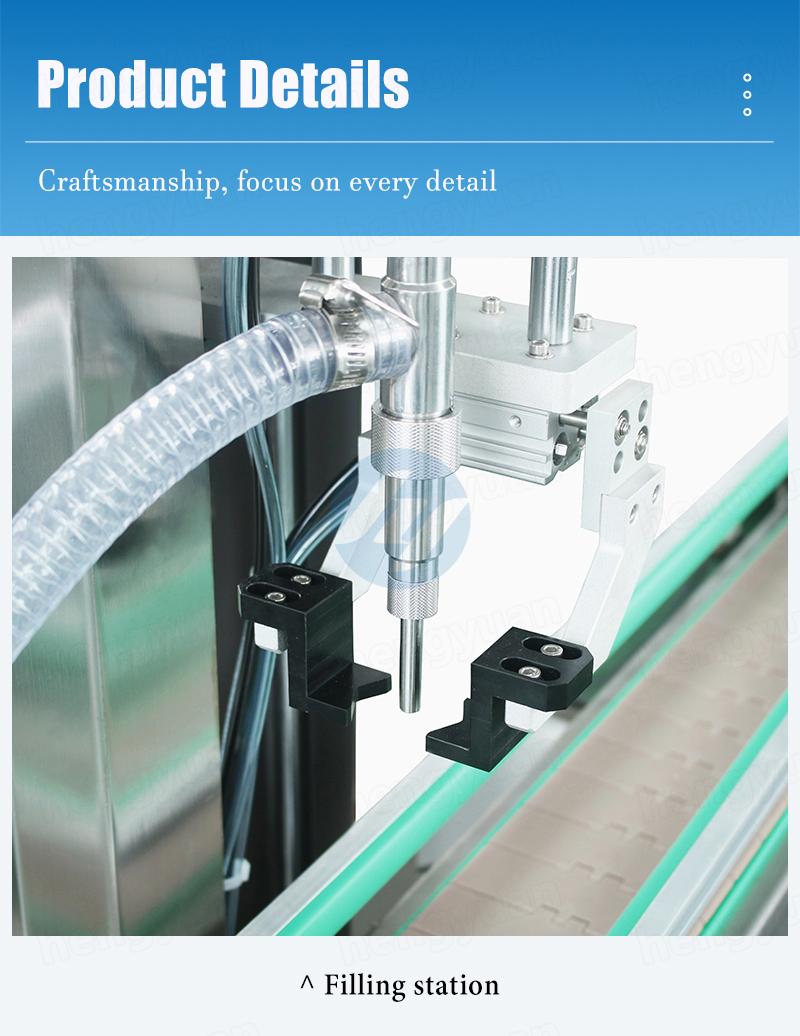

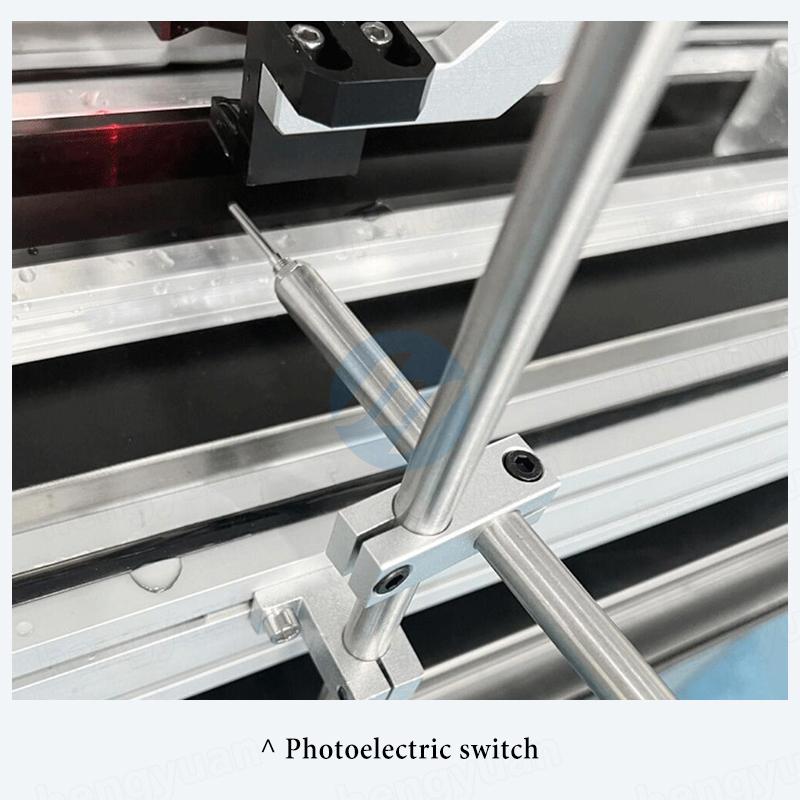

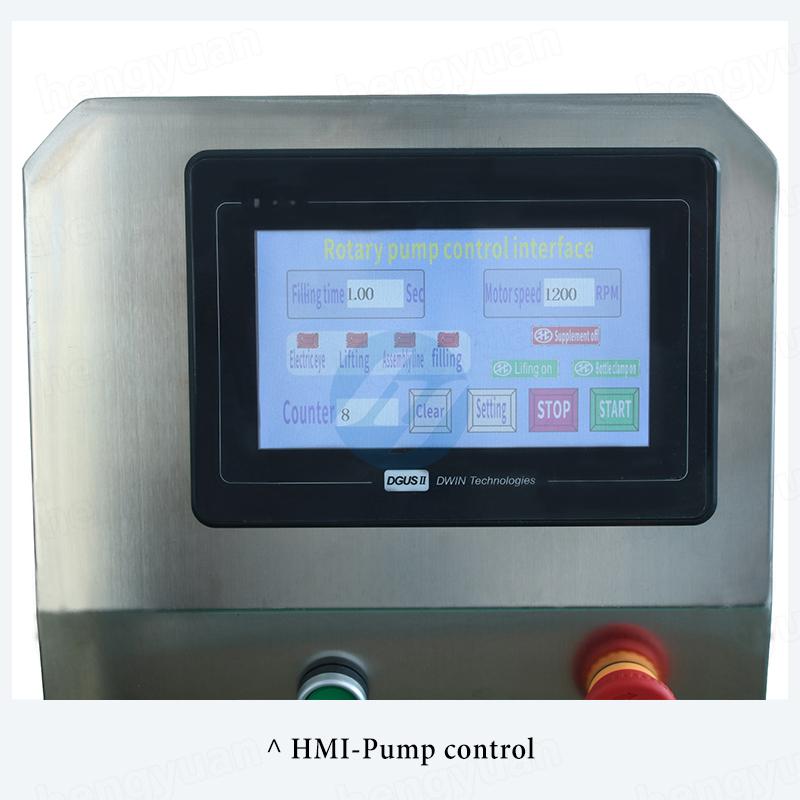

3) This filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action.

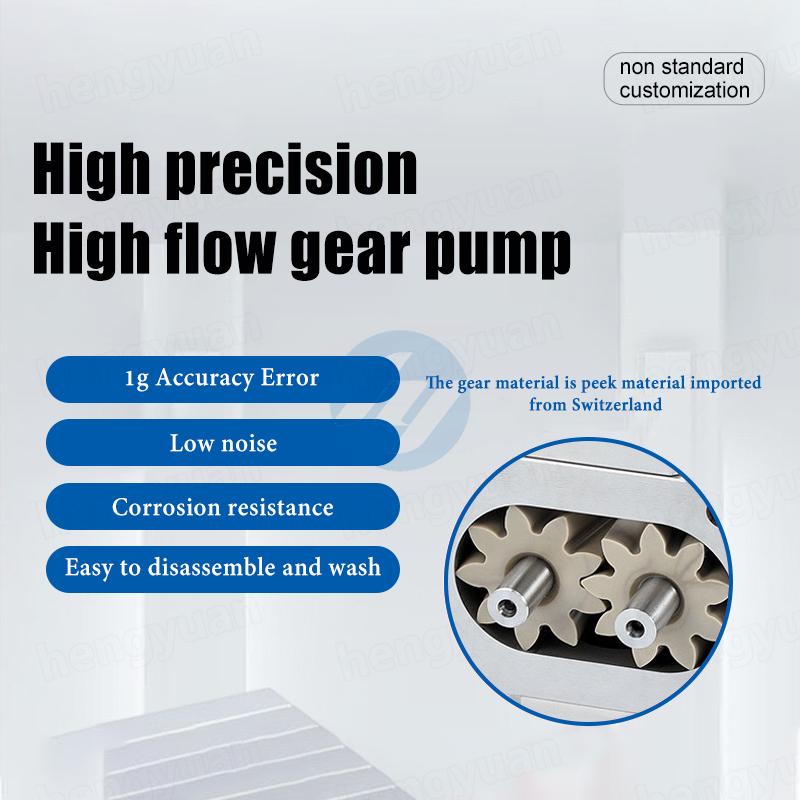

4) Accurate measurement: adopt servo control system with gear pump.

5) There is anti-leakage nozzle, prevent the liquid drop on conveyor cause pollution.

6) Convenient adjustment: replacement filling specifications only by setting on touch screen.

7) Wide range of application: unique pump head structure, can transport high viscosity pure materials. (As long as the flow can be filled).

8) Easy to wash: pour clean water into the equipment and wash it with high-speed circulating water, which is convenient and sanitary.

Click here to view HYGP-A100 Automatic Desktop Gear Pump Dosing Filling Machine running video on YouTube