Description

Product Application

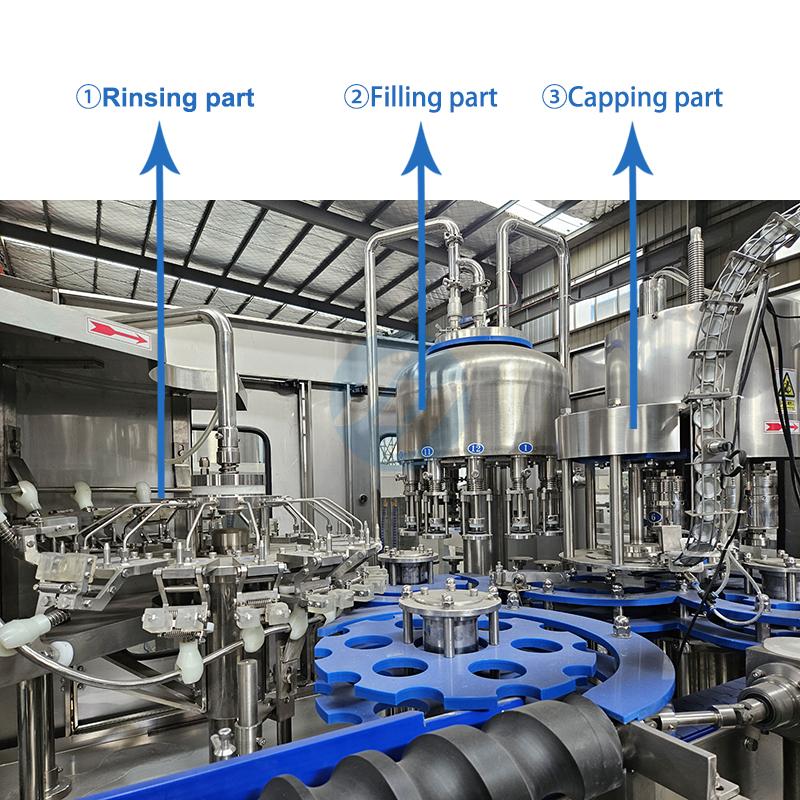

This rotary glass bottles ring filling and lug lid twist-off capping machine adopts PLC programmable control and touch screen parameter setting. It is an advanced rinsing filling capping system integrating machine, combine sensor detector, electricity and compressed air. It has automatic gravity flow, same lqiuid level control measurement and man-machine interface operation system. It can be used for liquid filling without gas, automatic control of feeding; no bottle no filling. It is convenient to change the bottles with same bottle mouth size, change the filling specification only need to change the bottle body clamping plates. It is suitable for both cold and hot filling of liquid without gas. With vaccum suction function, the scums can be removed without polution.

It has automatic calculation cleaning function. It has a liquid container on the above side. Then the liquid is buffered, the liquid level in the container is controlled at the same, when liquid level is less, the inlet valve will open and pump will work to inlet liquid from user’s liquid tank.

For cleaning process, the machine is made of SUS304 stainless steel, and can be washed easily. There need one cycle bottles to assist the circulation cleaning.

It is an ideal automatic filling equipment for beverage drinking liquid bottling. It has the characteristics of high filling precision, simple operation, convenient maintenance and labor saving.

Application

Automatic bottle rinsing filling and capping machine, juice glass bottles rinsing filling and capping machine, orange juice glass bottle rinsing filling and lug lid twist-off capping machine, Apple juice glass bottle dispensing machine, Grape juice glass bottle filler with capper machine, mango juice bottle filling and capping machine, milk glass bottle rinsing filling and capping machine, tea drinking glass bottle filling and capping machine, etc. Rotary rinsing filling and capping machine.

|

Technical Parameters |

|||||||

|

Model |

8-8-4 |

18-18-6 |

24-24-8 |

32-32-10 |

40-40-12 |

50-50-15 |

60-60-15 |

|

Rinsing Heads |

8 | 18 | 24 | 32 | 40 | 50 | 60 |

|

Filling Heads |

8 | 18 | 24 | 32 | 40 | 50 | 60 |

|

Capping Heads |

4 | 6 | 8 | 10 | 12 | 15 | 15 |

|

500ml Bottle Capacity (BPH) |

3000 | 6000 | 9000 | 12000 | 15000 | 19000 | 23000 |

|

Volume |

100-1500ml |

||||||

|

Accuracy |

≤1000ml: ±2ml; 100-500ml: ±1ml; ≤100m: ≤1ml |

||||||

|

Suitable Bottles |

Height: 100-280mm, Diameter: Φ30-110mm |

||||||

|

Control Method |

Touch screen and PLC |

||||||

|

Air Supply |

0.5-0.7Mpa |

||||||

|

Voltage |

415V/380V/220V, Three Phases , 50/60Hz, customized globally |

||||||

Main Features

1) Simple structure in rotary type, easy in installation and maintenance.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) This filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action.

4) Accurate measurement: adopt gravity filling plus suction back system, ensure the liquid level same.

5) When close to target filling capacity can be applied to realize speed slow filling, prevent the liquid spill bottle mouth cause pollution.

6) Convenient adjustment: replacement filling specifications only change rotating plates.

7) Suitable material: water, juice, milk tea, tea drinking, enery drinking etc. beverage drinking without gas.