Description

HYFPC-100PP Automatic Bottle Filling Rubber Plugging & Crimping Capping Machine

Product Introduction

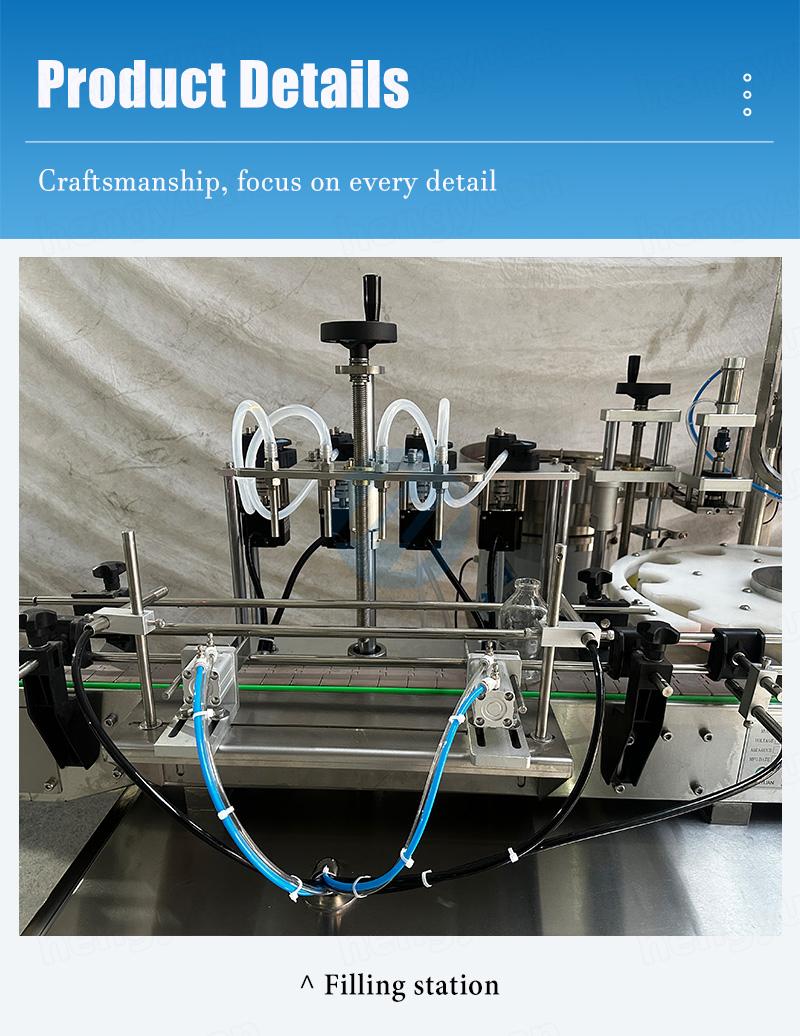

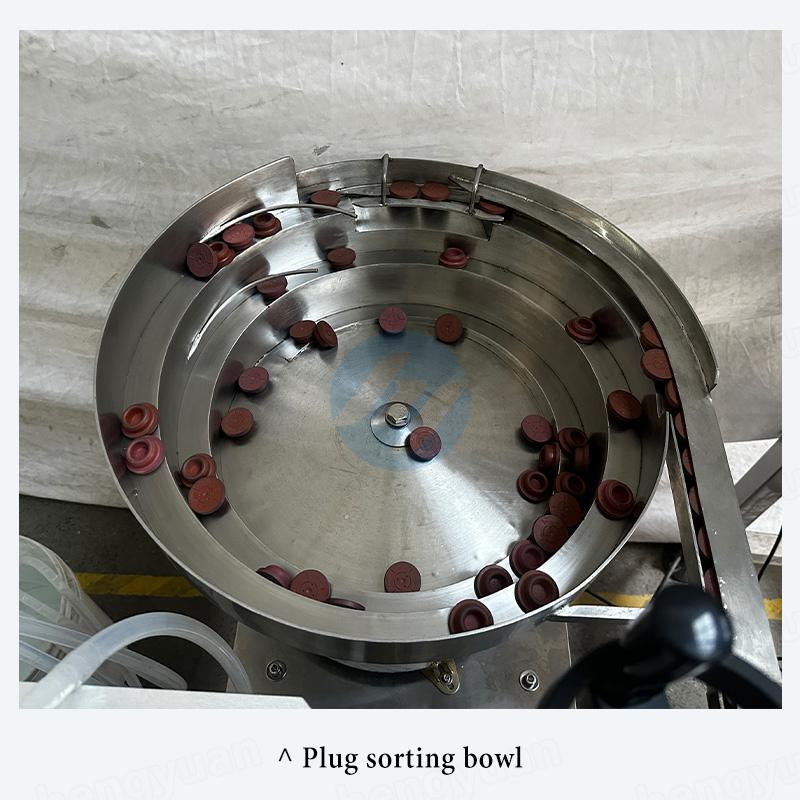

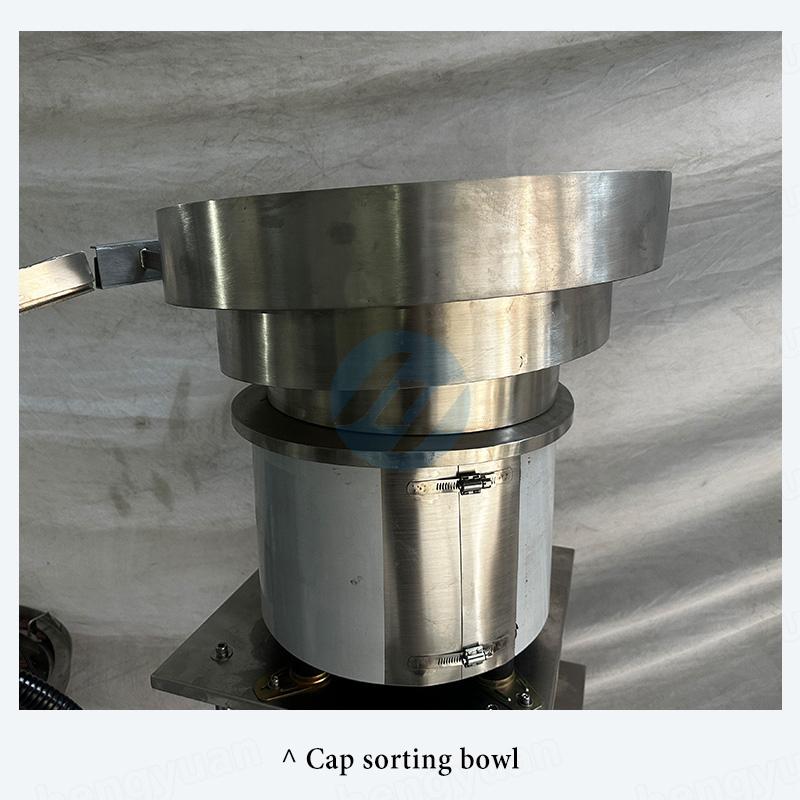

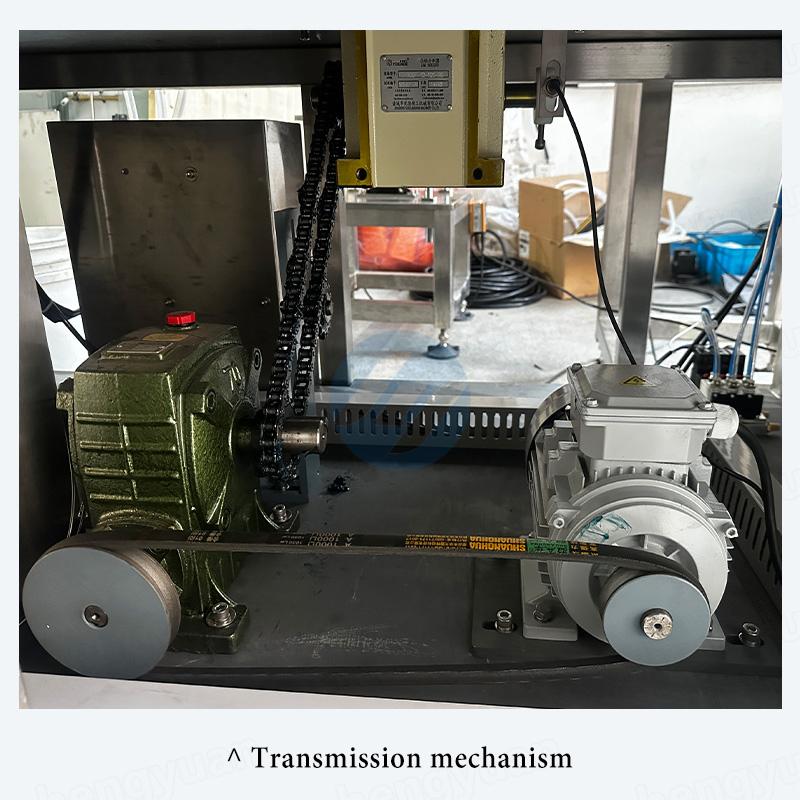

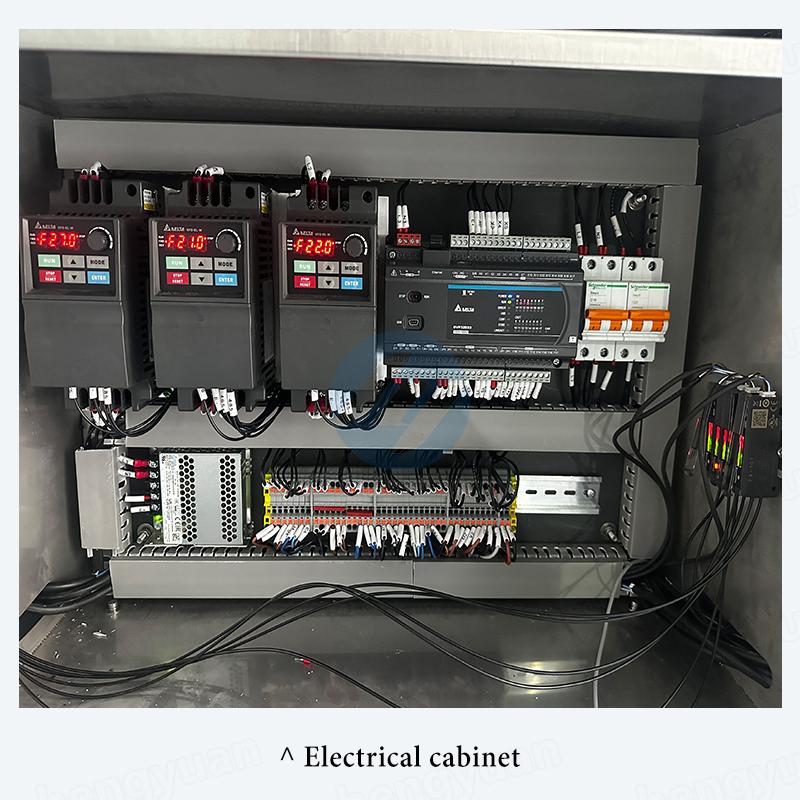

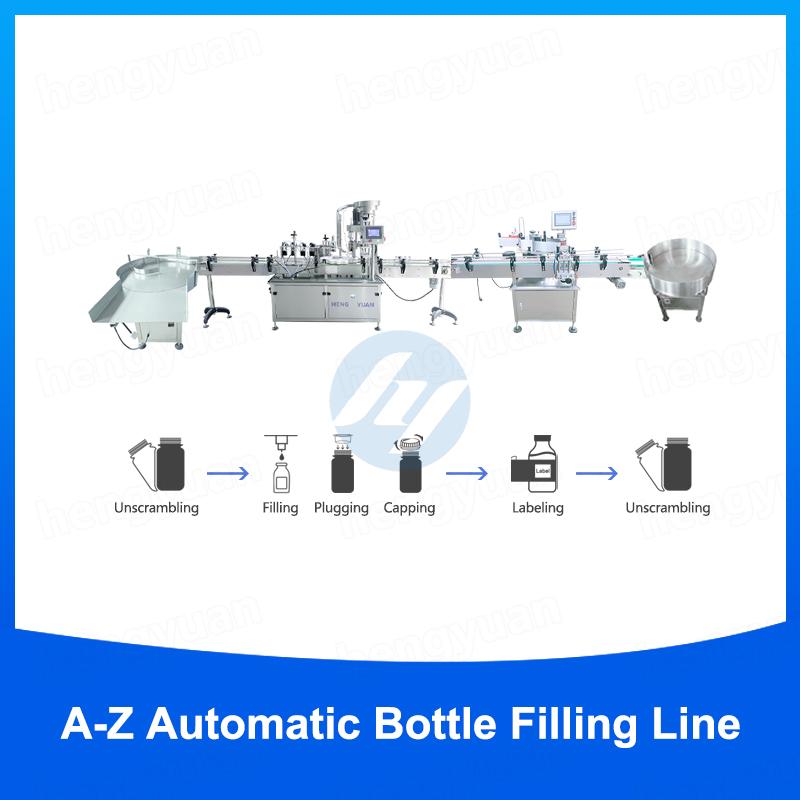

Introduction to Automatic Bottle Filling, Rubber Plugging, and Crimping Capping Machine: This is an intelligent equipment integrating mechanical, electrical, and photoelectric technologies. It utilizes PLC (Programmable Logic Controller) and a touchscreen interface to control each action and adjust parameters with precision. Designed for filling bottles, applying rubber plugs, and crimping caps, this machine employs a peristaltic pump filling method, which facilitates easy cleaning of the piping and is suitable for liquids with good fluidity. The filling method can also be customized according to customer needs, including piston cylinder, gear pump, diaphragm pump, rotor pump, and gravity feed, to accommodate various material filling requirements. The internal plug and external cap stations are integrated onto a turntable, ensuring accurate positioning. With only standard packaging materials provided by the customer, this machine achieves efficient sealing. Both the internal plug and external cap stations can be matched with different sealing methods based on various packaging materials.

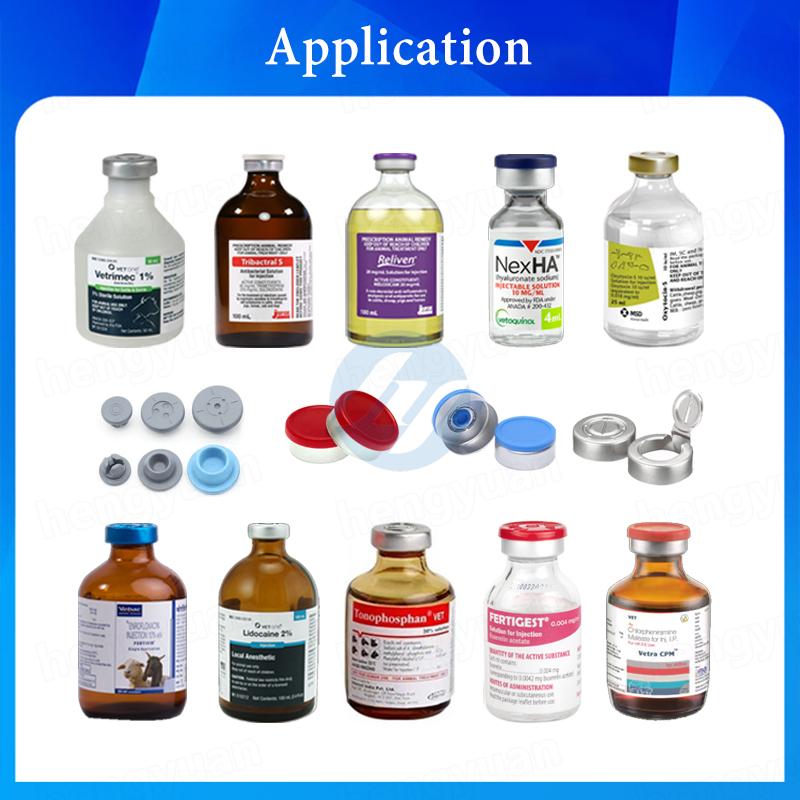

Application

Product Introduction

Introduction to Automatic Bottle Filling, Rubber Plugging, and Crimping Capping Machine: This is an intelligent equipment integrating mechanical, electrical, and photoelectric technologies. It utilizes PLC (Programmable Logic Controller) and a touchscreen interface to control each action and adjust parameters with precision. Designed for filling bottles, applying rubber plugs, and crimping caps, this machine employs a peristaltic pump filling method, which facilitates easy cleaning of the piping and is suitable for liquids with good fluidity. The filling method can also be customized according to customer needs, including piston cylinder, gear pump, diaphragm pump, rotor pump, and gravity feed, to accommodate various material filling requirements. The internal plug and external cap stations are integrated onto a turntable, ensuring accurate positioning. With only standard packaging materials provided by the customer, this machine achieves efficient sealing. Both the internal plug and external cap stations can be matched with different sealing methods based on various packaging materials.

Application

This versatile machine can be customized for filling and sealing a wide range of products, making it widely applicable in industries such as cosmetics, personal care, household chemicals, agrochemicals, food, and more.

Main Features

Six features of the Automatic Bottle Filling, Rubber Plugging, and Crimping Capping Machine:

1)Integrated Technology: Combines mechanical, electrical, and photoelectric technologies to create an intelligent and efficient machine.

2)PLC & Touchscreen Control: Utilizes PLC for programming and a touchscreen interface for intuitive control and parameter adjustment.

3)Flexible Filling Methods: Offers multiple filling options, including peristaltic pump, piston cylinder, gear pump, diaphragm pump, rotor pump, and gravity feed, to accommodate different material characteristics and customer needs.

4)Easy Cleaning: The peristaltic pump filling method allows for easy cleaning of the piping, ensuring hygiene and minimizing maintenance downtime.

5)Precise Positioning & Sealing: Features an integrated turntable for precise positioning of internal plugs and external caps, enabling efficient and accurate sealing with various packaging materials.

6)Versatile Applications: Customizable for filling and sealing a wide range of products, making it suitable for industries such as cosmetics, personal care, household chemicals, agrochemicals, food, and more.

Machine Display

Click here to view HYFPC-100PP Automatic Bottle Filling Rubber Plugging & Crimping Capping Machine running video on YouTube