Description

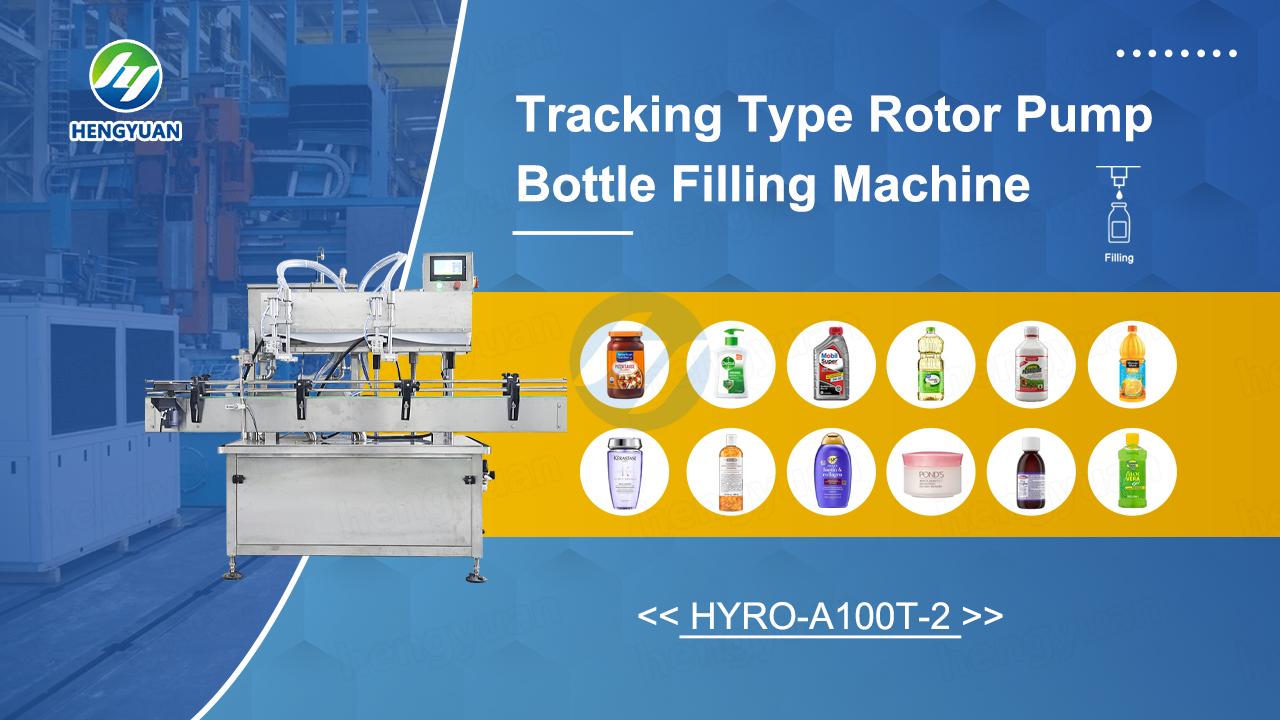

Product Introduction

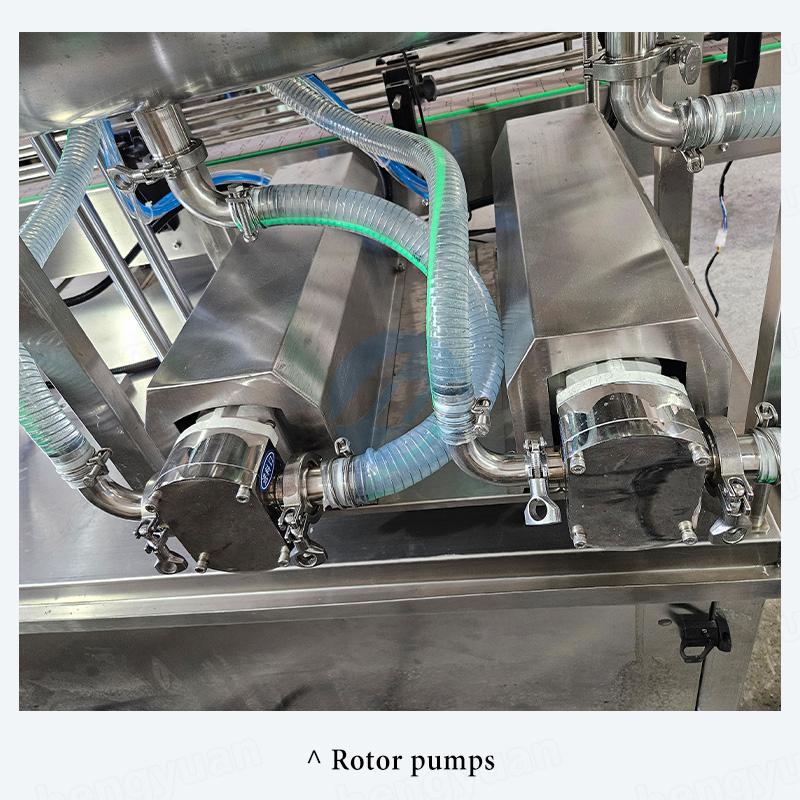

This servo-driven rotor pump filling machine is designed for precision filling of liquids, semi-fluids, pastes, and particle-laden sauces across various industries including food & beverage, cosmetics, personal care, chemicals, and pharmaceuticals. Its linear filling mechanism accommodates diverse container types without modification. Featuring PLC control with touchscreen HMI, the system automates bottle feeding, speed-adjustable tracking filling, and discharge processes for optimal efficiency.

Product application

For examples: tracking type Dish Washing Detergent Bottle filling machine, none-stop bottle liquid filling machine, tracking type facial toner water filling machine, moisturizing water piston filling machine, facial toner filling machine, shampoo filling machine, hair conditioner filling machine, handwashing liquid filling machine, liquid soap filler, shower gel dispensing machine, laundry detergent bottle filler, facial toner filling machine, hand sanitizer filler, facial cream filler, sauce bottle filler, gel dispensing machine, viscous liquid filler, lubricant filler, etc.

HYRO-A100T-2 Tracking Type Bottle Filling Machine

Technical Parameters

Model

HYRO-A100T-2

Heads

2pc ( 1 and 4, 6, 8 pcs available )

Capacity(BPH)

200ml: Approx 3000

Volume

10-1000ml customized ( other volume is availabel : 200-2000ml, 500-5000ml)

Accuracy

≤±0.5%

Suitable Bottles

Height: 100-280mm, Diameter: Φ30-110mm, (can be customized)

Control method

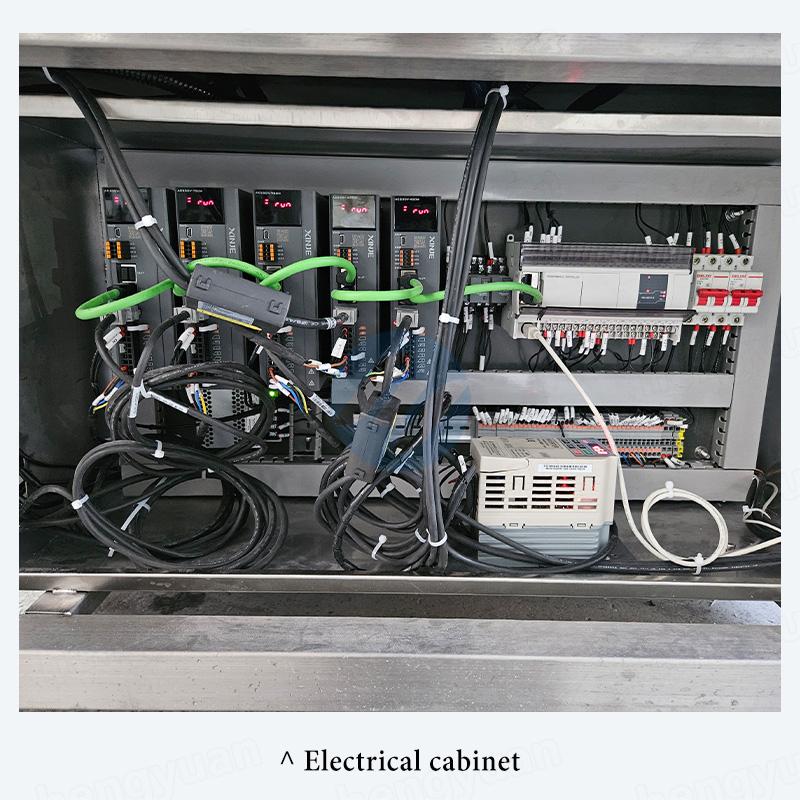

Touch screen and PLC

Air supply

0.5-0.7Mpa

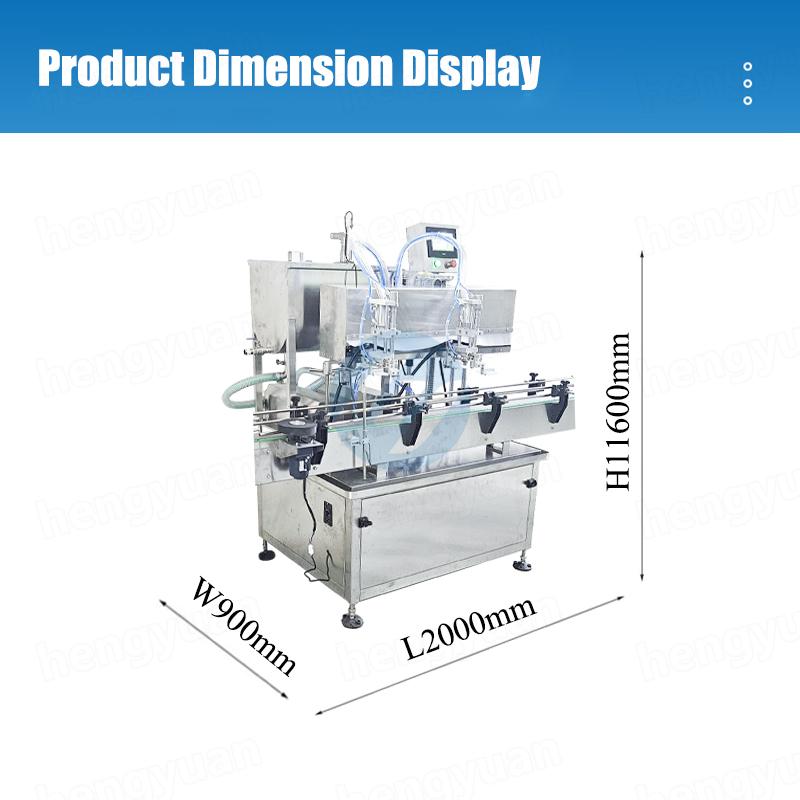

Dimension

200x110x180cm ( without frame cover)

Power supply

3.5kw

Voltage

415V/380V/220V/110V, Three Phases/One phase , 50/60Hz, customized globally

Main Features

1)Wide Material Compatibility – Handles products from low-viscosity water-based solutions to thick pastes and granular mixtures

2)Hygienic 304 Stainless Steel Construction – Full stainless steel frame and food-grade contact surfaces

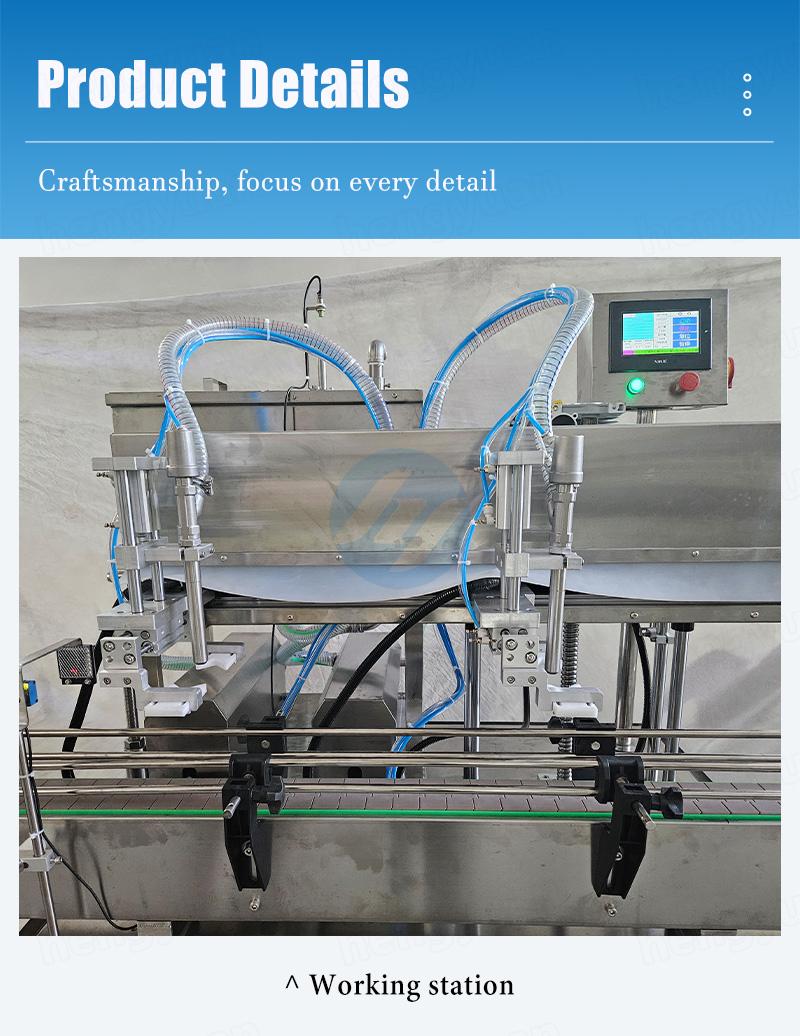

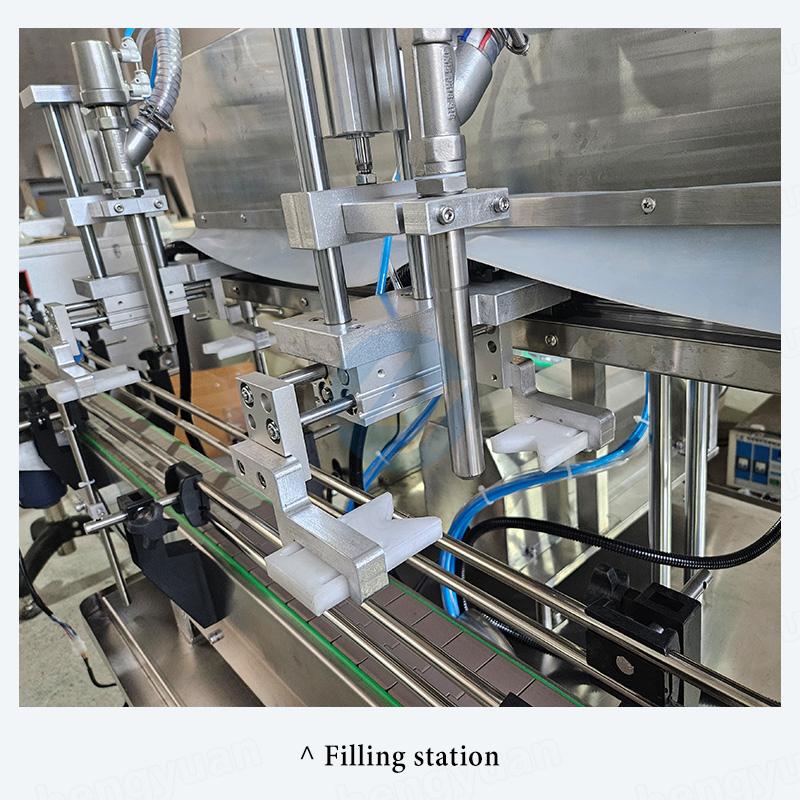

3)Smart Diving Filling Technology – Cylinder-actuated filling head minimizes foam generation and prevents nozzle drippage

4)Residual Material Optimization – Circular-bottom tank design with low-point drainage ensures ≤1% material waste

5)Intelligent Bottle Detection – Photoelectric sensors prevent accidental dispensing without containers

6)Industrial-Grade Control System – Waterproof electrical cabinet with imported PLC, relays, and pneumatic components

7)User-Friendly Operation – 7" color touchscreen with preset programs for different container sizes and fill volumes

8)The machine requires no additional accessories for basic operation and features tool-free adjustment mechanisms for rapid product changeovers.

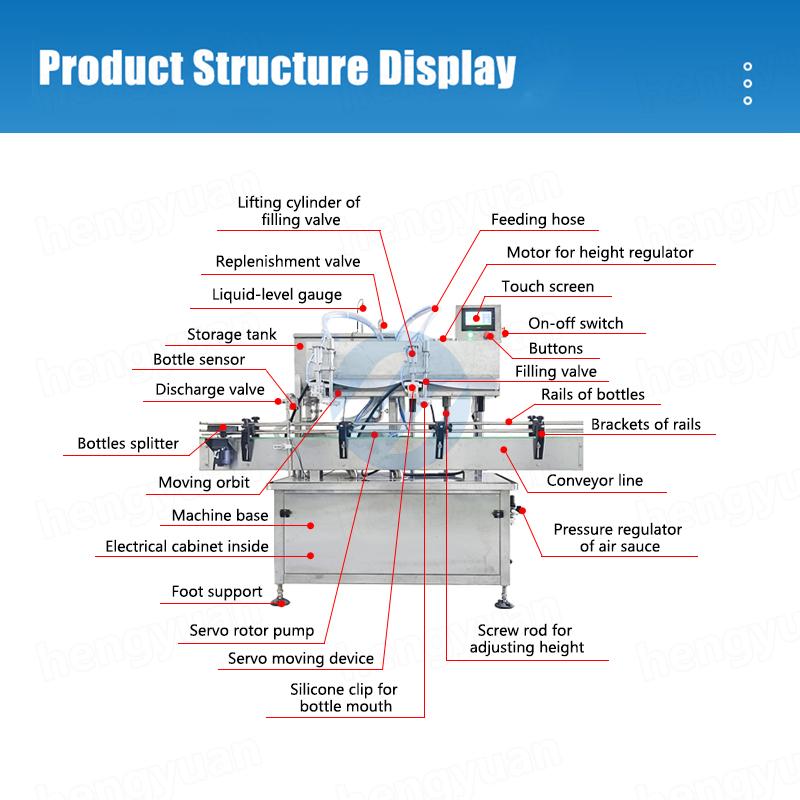

Machine Display

Click here to view HYRO-A100T-2 Tracking Type Bottle Filling Machine running video on YouTube