Description

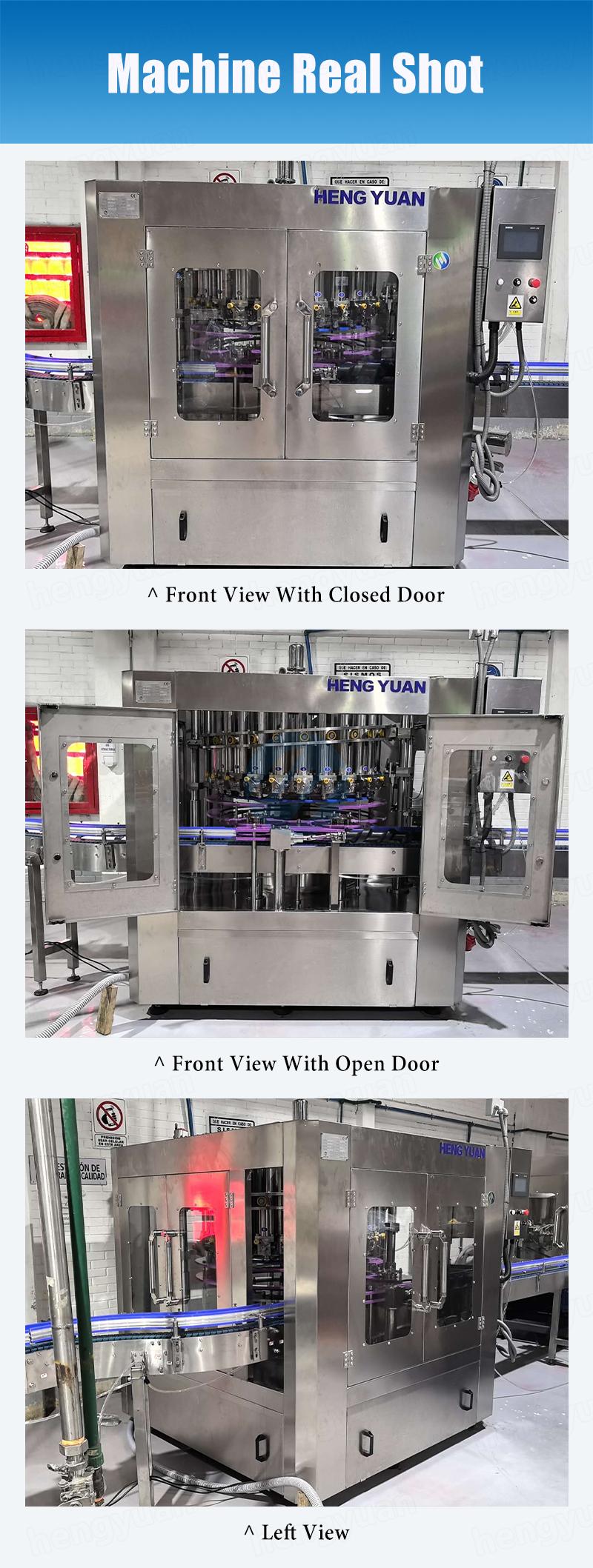

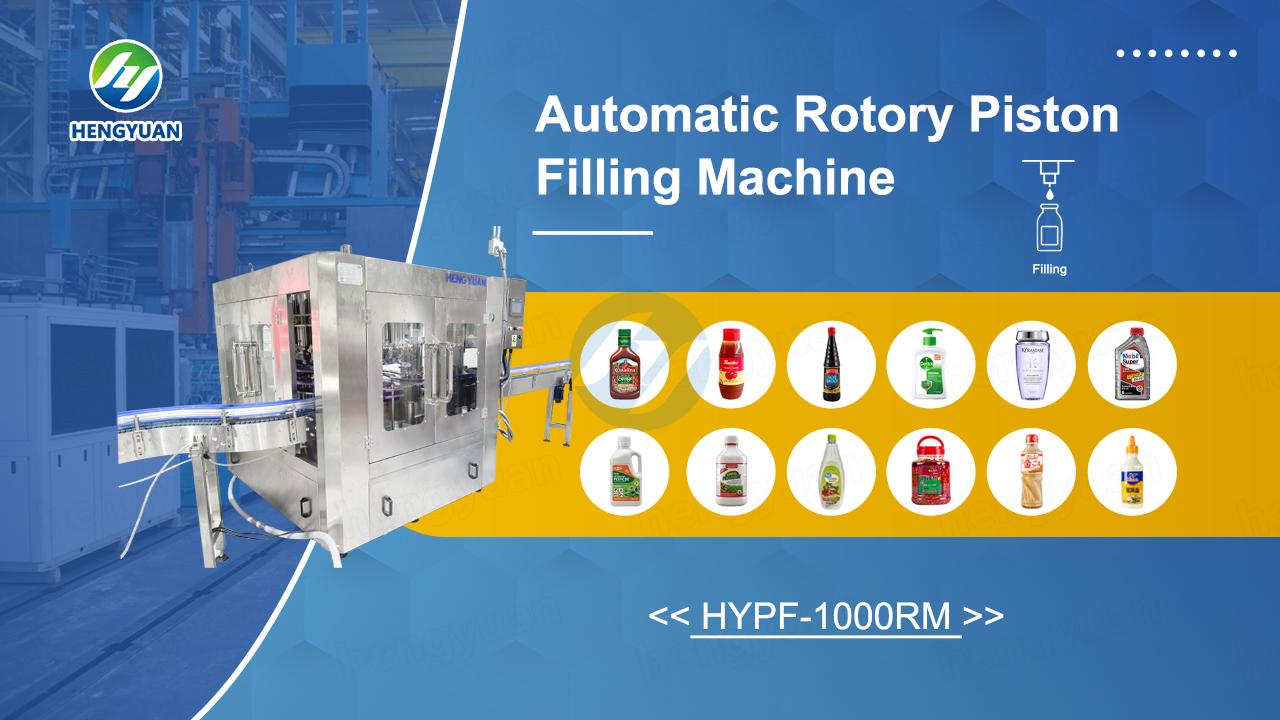

HYPF-1000RM Automatic Rotary Piston Dosing Filling Machine

Product Introduction

Our rotary piston filling machine is engineered for precision dosing and filling of viscous liquids, creams, and sauces—including products with particulates or high concentration levels. Constructed with corrosion-resistant stainless steel throughout the filling system, it ensures product hygiene, meets stringent sanitary standards, and enhances equipment durability.Utilizing an efficient rotary piston mechanism with variable frequency drive speed control, the machine delivers smooth, high-speed operation at rates from 50 to 200 bottles per minute (customizable). It supports filling volumes of up to 1 liter per container with consistent accuracy. The system incorporates soft start and soft stop functions to eliminate rigid impacts and prevent container damage, making it an ideal solution for reliable and hygienic filling across food, pharmaceutical, and cosmetic industries.

Product Application

Edible oil filling machine, Dialysis, Pesticide filling machine, Chili sauce filling machine, Milk filling machine, Soybean sauce filling machine, vegetable paste filling machine, liquid filling machine etc. Any liquid, half-flowing liquid, viscous cream, liquid filler, refill equipment, Vaseline filling machine, paraffin wax filler, hand sanitizer filler, facial cream filler, etc.

Technical parameters

Filling heads(pcs)

12

18

24

32

40

Capacity(BPH, 500ml)

3000

4500

6000

8000

10000

Filling Volume

50-1000ml

Accuracy

≤±1%

Suitable Botles

Customized

Control method

Buttons or PLC+Touch screen

Power(kW)

5.5

7

9

12

15

Voltage

AC110V/220V/240V/380V/415V, globally customized by using a transformer

Size(LxWxH)cm

110x100x220

130x120x220

160x140x220

200x190x220

230x215x220

Key Advantages

1. High-Speed Rotary Operation

Capable of filling 50–200 bottles per minute (BPM) with continuous rotary motion, ensuring high production efficiency and smooth container handling.

2. Premium International Components

Equipped with world-renowned pneumatic, electrical, and control components for enhanced reliability, precision, and long-term performance.

3. Intelligent Control System

Features PLC-based automation with a user-friendly touchscreen interface for easy operation, recipe storage, and real-time monitoring.

4. Precision Piston Dosing

Utilizes piston-cylinder metering to ensure highly accurate and repeatable fills, with consistent positioning for uniform dosing across all containers.

5. Broad Material Compatibility

Suitable for a wide variety of products including liquids, viscous fluids, creams, gels, pastes, and particle-laden sauces.

6. Flexible Container Adaptation

Easily adjustable to accommodate diverse bottle sizes and shapes, enabling quick changeover and support for multi-product production lines.