Description

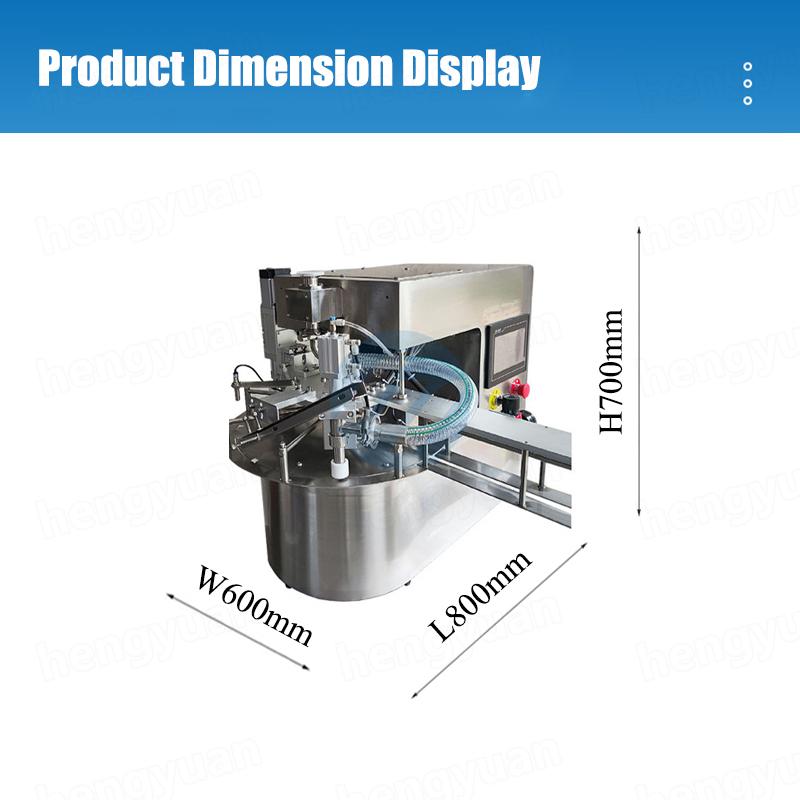

HYRFC-100CG Automatic Filling and

Capping Machine for Spout Pouch

Product Introduction

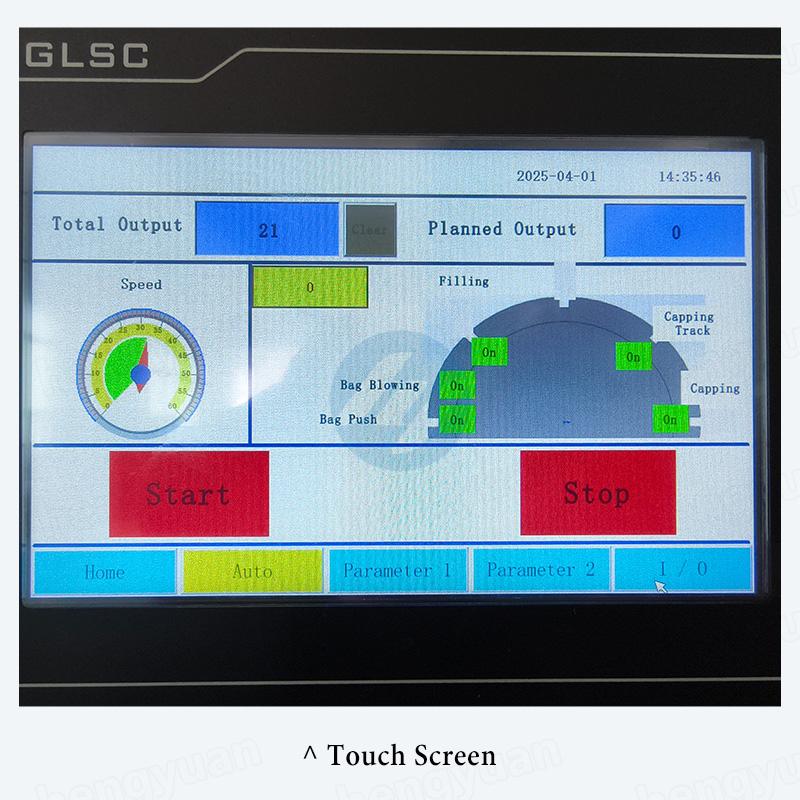

The spout pouch filling and capping machine is generally used for filling and capping spout pouch for packaging liquid. It adopts PLC programmable control and touch screen parameter setting. It is an advanced filling capping system integrating machine, combine sensor detector, electricity and compressed air.The machine can process different designs of pouches as long as all different size pouches have the same shape/size spout & cap. Our company can also according to the different requirements of customers to increase other functions, such as connecting CIP cleaning, vacuum & nitrogen injection, etc, to meet customer demand. This machine is used for a variety of products, such as jelly, milk, butter, fruit juices, paste, chemical liquid etc widely. High reliability, convenient operation, wide applicability, high performance.

Application

Automatic spout pouch liquid filling capping machine, spout pouch jelly filling capping machine, spout pouch milk filling capping machine, spout pouch soybean milk filling capping machine, spout pouch fruit juice filling capping machine, spout pouch seasoning packing machine, spout pouch liquid detergent filling capping machine, spout pouch laundry detergent filling capping machine, spout pouch edible oil filling capping machine, spout pouch lubricant oil filling capping machine, etc.

HYRFC-100CG Automatic Filling and Capping Machine for Spout Pouch

Main Features

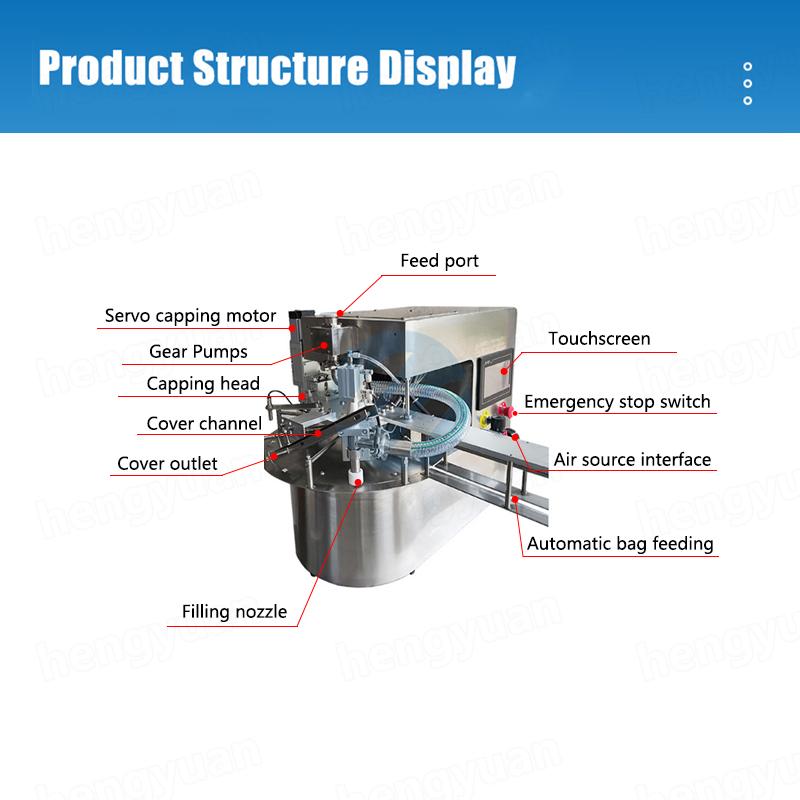

1. Variable Frequency and Speed Control: Equipped with a variable frequency variable speed system, this machine allows for precise regulation of the production rate to accommodate varying operational needs.

2. Accurate Positioning: The precise indexer ensures accurate turn plate positioning, facilitating seamless and error-free operation during the filling and capping process.

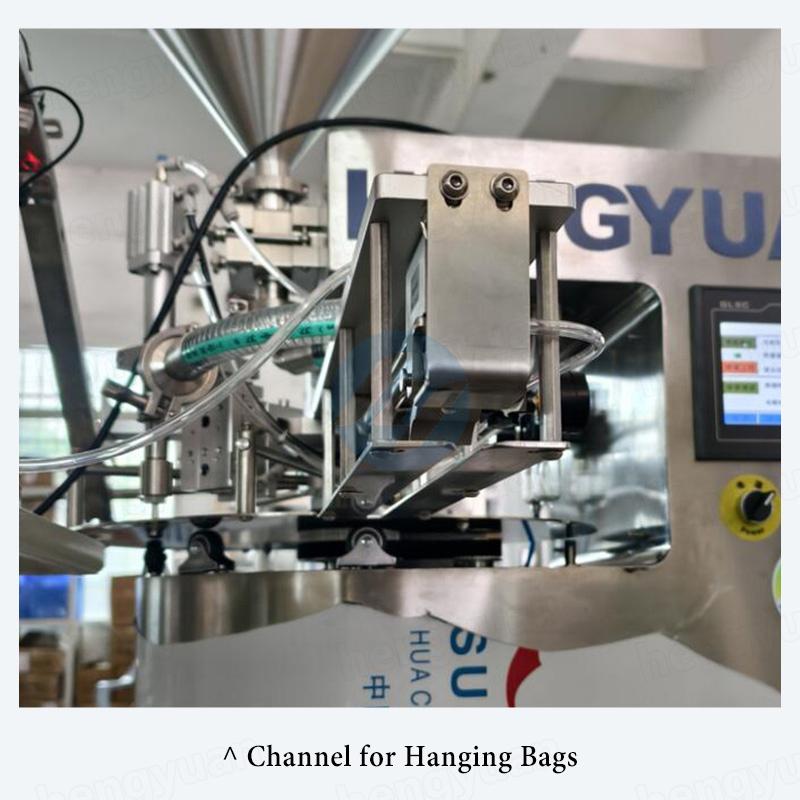

3. Automated Pouch Feeding: Designed to reduce labor intensity, the machine features an automatic pouch feeding mechanism that streamlines the production process, enhancing efficiency and minimizing manual intervention.

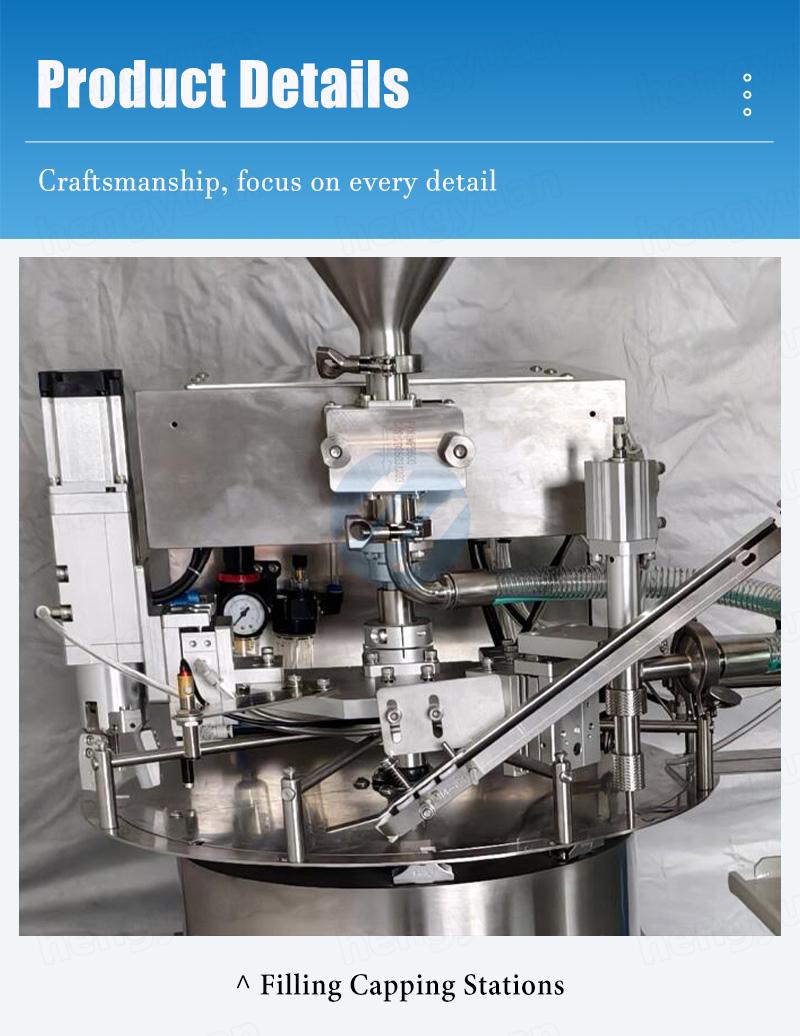

4. High-Precision Filling: The machine adopts a specialized metering device to ensure accurate filling amounts, catering to different product volumes with precision and reliability.

5. Insert-Type Liquid Filling: This innovative filling method effectively avoids liquid splashing and bubbling, ensuring a clean and efficient filling process.

6. Servo-Adjustable Cap Handling and Tightening: The machine comes with a servo adjustable cap handling and tightening device, guaranteeing that caps are firmly and consistently tightened, enhancing product integrity and safety.

7. Robust Construction: Built with a stainless steel rack, electroplated pressing plate, and 304 stainless steel plate housing, this machine offers durability and resistance to corrosion, ensuring long-term reliability and performance.

8. User-Friendly and Efficient Operation:

* Applicability: Suitable for a wide range of bag-packaged products in the daily chemical and food industries, including laundry detergent, shampoo, jelly, milk, etc.

* Easy Operation: Digitalized machine adjustment enables simple parameter setting. Once parameters are saved for a specific spout pouch type, only the product volume needs adjustment, making operation straightforward and efficient.

* High Efficiency and Precision: Rapid filling speed with excellent stability. Each filling volume is independently controlled by a servo motor, ensuring high filling accuracy and consistency.

* Easy Cleaning: The gear pump, storage tank, and filling head are secured with clamp-type connections, allowing for localized disassembly and cleaning without tools. An automatic cleaning button is provided on the main control screen for added convenience.

Click here to view HYRFC-100CG Automatic Filling and Capping Machine for Spout Pouch running video on YouTube